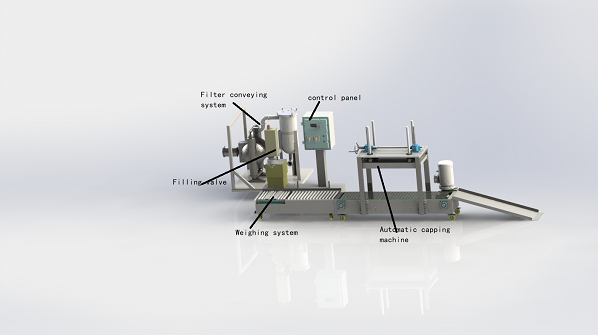

Automatic ink filling machine

Function introduction

■ the materials are transported by the pump, filtered by the bag filter, and transported to the inlet of the filling machine. Manual empty barrel, automatic machine filling, manual capping, automatic machine delivery capping

■ digital input freely sets the target value (filling weight)

■ two filling methods of net weight / gross weight can be freely selected

■ the filling head is independently designed and developed by our company. It has the functions of rapid disassembly and assembly by hand, size change, easy cleaning and anti dripping

■ the filling head can be manually adjusted in height, suitable for a variety of different specifications of cans

■ the independently developed control system adopts high-end hardware, with fast response speed, simple operation and reliable performance

■ the system has the function of automatically correcting the adjustment error and can be opened / closed freely

■ two stage adjustable filling mode is adopted to complete the filling quickly and accurately, ensuring the efficiency to the maximum

■ automatic discrimination of empty barrel tare weight range and no barrel filling function

■ the sealing, soft connection and direct contact parts with materials are made of 304 stainless steel + Teflon

■ the controller is equipped with manual buttons for all actions, emergency stop, manual feeding and other buttons for special use

■ the whole machine is made of stainless steel, the direct contact part of materials is made of 304 stainless steel, and a small number of stressed parts such as gland, controller and lifting system are made of carbon steel

■ the controller display can timely display the weighing value, time and date, accumulated filling barrels, accumulated total filling weight and other information

■ during continuous filling, the system will automatically start filling without pressing other switches again

Basic parameters

■ maximum weighing capacity: 50kg ■ minimum sensing capacity: 0.001kg

■ filling error: ± 5g ■ filling speed: 6 ~ 7 barrels / minute (depending on the feed flow rate)

■ control mode: two gear control ■ filling mode: on the barrel mouth, fixed type

■ air source interface: 10mm air pipe interface ■ power supply: 380V / 50Hz wire provided by the user to the machine side

■ air source: 04mpa-0.8mpa 10mm air pipe (provided by the user to the machine side)

■ service temperature: - 10 ℃ - 50 ℃

■ foundation conditions: horizontal solid concrete ground with concrete thickness not less than 10cm