Automatic checkweighing system

Product introduction:

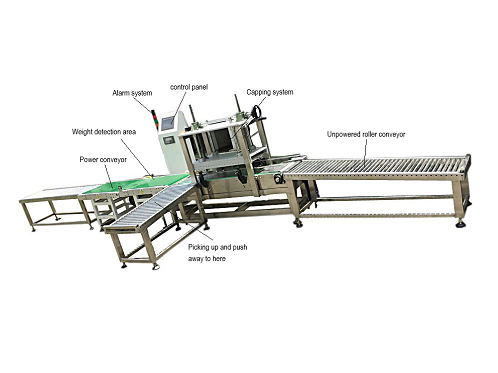

DCS-50-JZ-YG Automatic checkweighing system. It consists of a conveying system, a detection system, a capping system and a rejection system. The frame is made of aluminum alloy profiles,and the control system uses a 10-inch touch screen, which is nice and durable.

Product model:

DCS-50-JZ-YG Automatic checkweighing system

Product details:

DCS-50-JZ-YG Automatic checkweighing system is a dynamic weighing scale:Suitable for the weight detection of various items in motion, so as to reach the weight requirements within the required tolerance range. When non-conforming products are detected will be picking up and push away by the sorting mechanism. Qualified products continue to be conveyed to the capping area for automatic capping, and then continue to the next required work area.

Technical indexes

|

Weight detection range

|

<30kg

|

Detected item shape

|

Suitable for most items

|

|

Allowable error range

|

>5g

|

power supply

|

AC380±10% 50HZ

|

|

Detection speed

|

Base on “detected item shape” and ”allowable error range”

|

Outlook size

|

3200x800x1400(mm)

|

Product features:

1. DCS-50-JZ-YG Automatic checkweighing system. The tested items are conveyed to the checkweighing area through a belt, and there will be an alarm when an unqualified product is detected. The sorting mechanism will pick up and push away the unqualified products. The qualified products will continue to be conveyed to the capping area for automatic capping, and then continue to the next required work area.

2. A set of weight detection system;

3. Two sets of power conveyor belts;

4. A set of rejection system

5. A set of capping system

6. The detection speed and the allowable error range can be adjusted based on demand;

7. Automatic zero tracking.

Field of application: It is suitable for the weight detection of various items in the state of movement, so as to reject the unqualified products through the sorting mechanism. The qualified products will continue to be conveyed to the capping area for automatic capping, and then continue to the next required work area.

Machine customization: Customized machines can be customized according to the actual conditions and needs of the customer's factory.